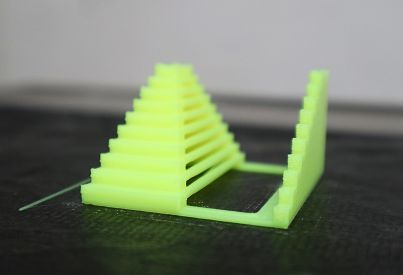

Detailed. Accuracy.

We have finely tuned our printers to operate with pinpoint accuracy, both complex and basic geometries can be achieved whilst retaining a perfect finish. We can achieve a professionally finished item that is end-user-ready.

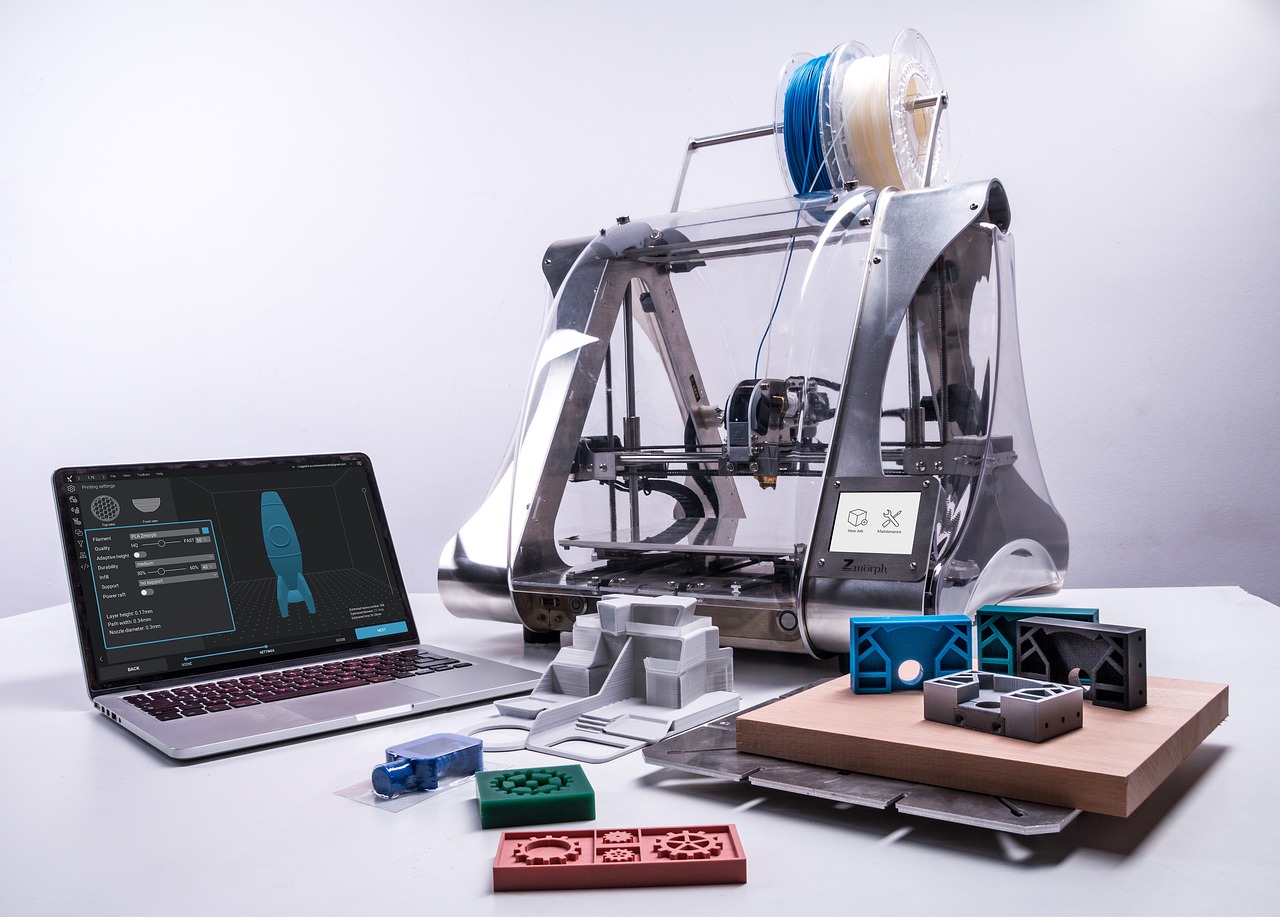

Our 3D Printing Capabilities

At PrintWorks we are able to 3D print a range of PLA, Wood-Fill PLA, Nylon, PETG, ABS, PC, Metal-Fill PLA, TPU and Resin to suit a variety of needs. We are your 3D printer for any engineering and design requirements.

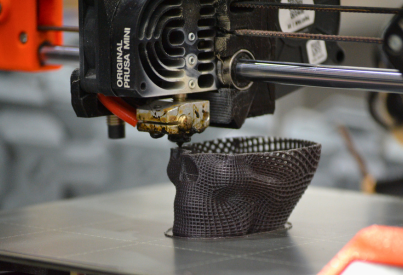

FDM (Fused Deposition Modeling)

FDM is the most popular, and conventional type of printing where most ideas start.

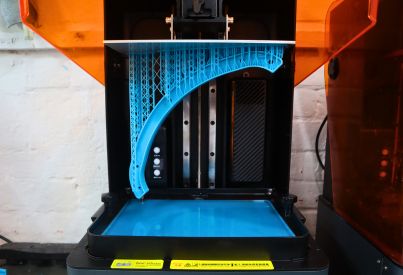

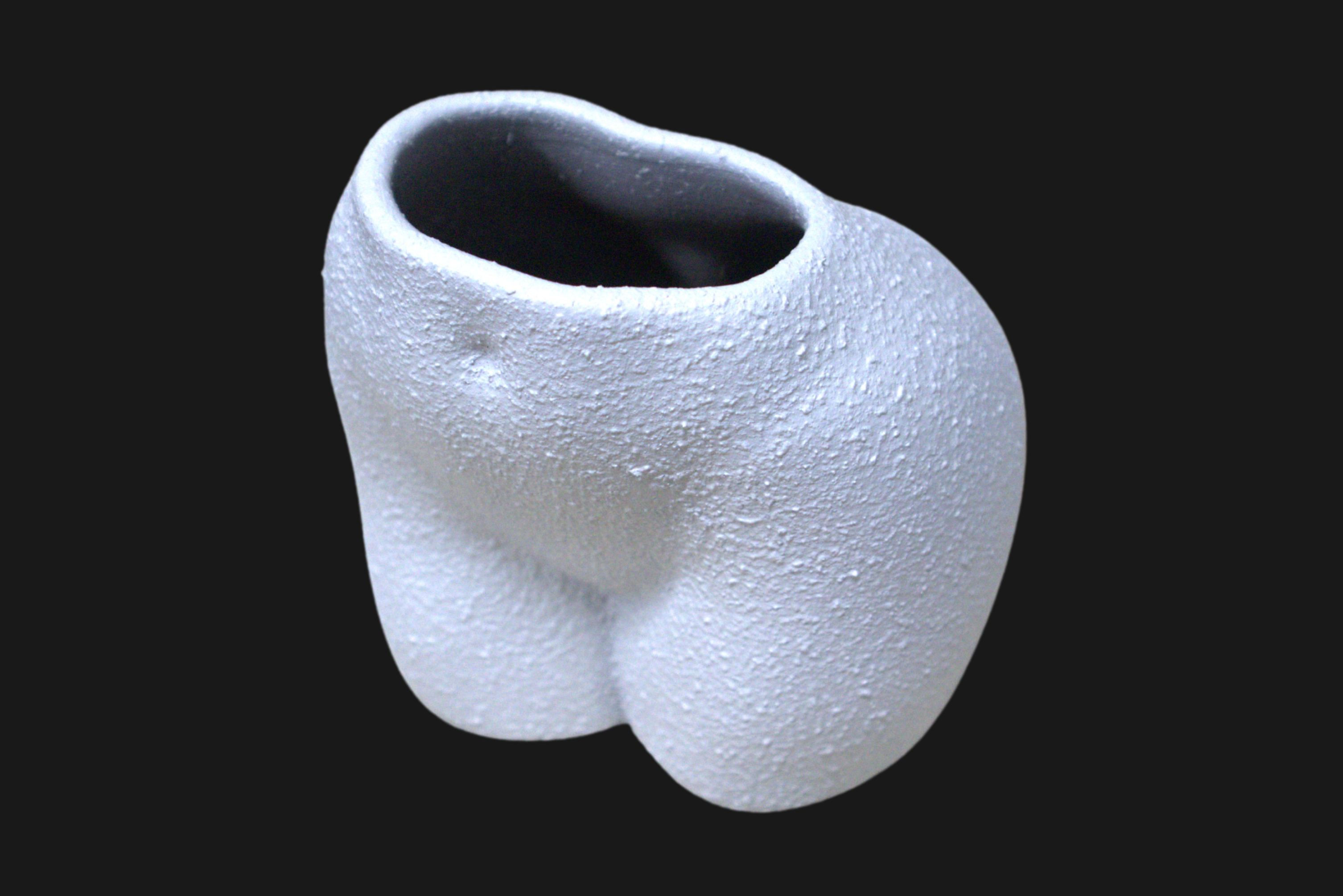

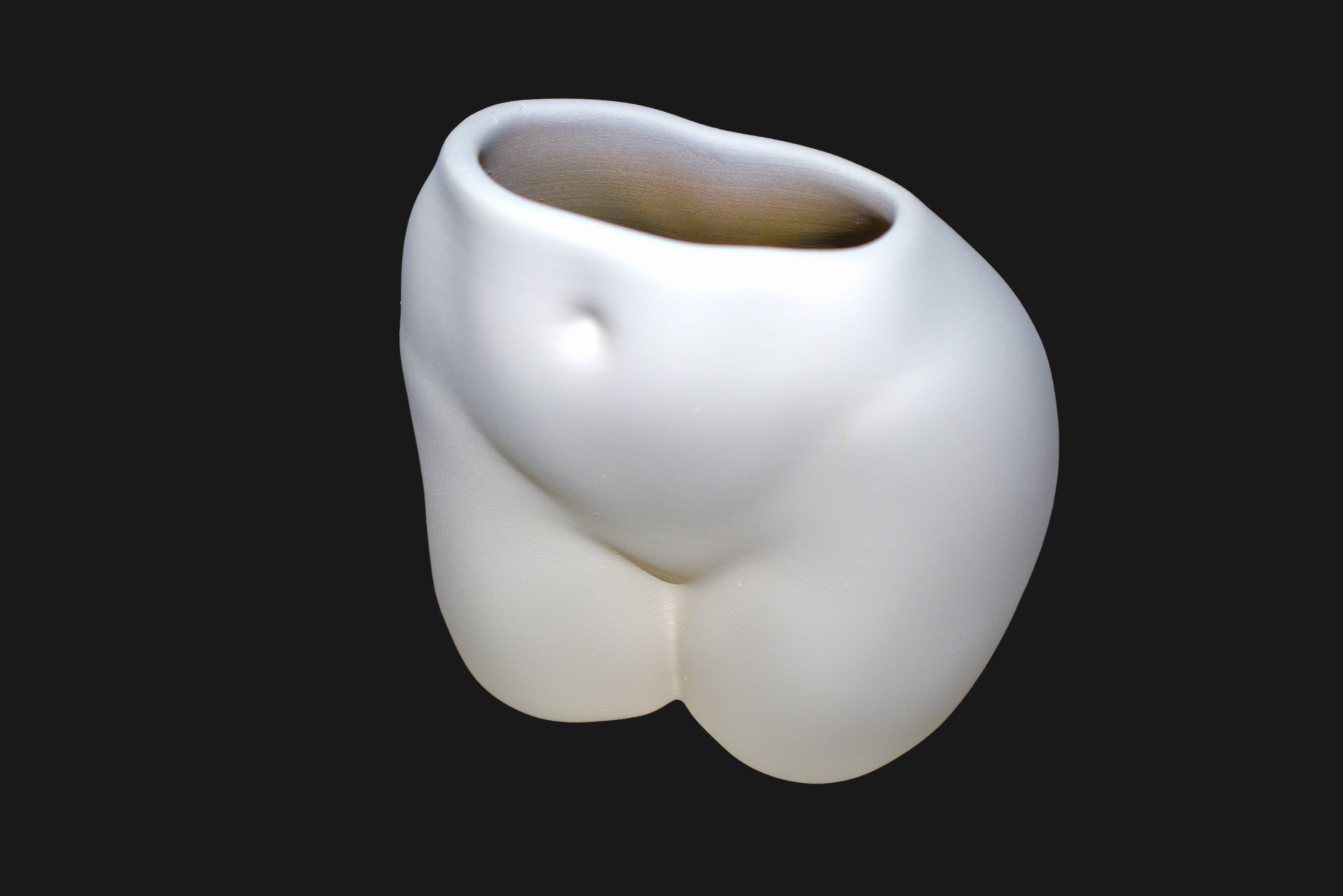

SLA (Stereolithography)

For achieving a fine finish where the small details count; this is the best option!

Prototyping

Making a 3D printed item look like a professionally manufactured, and end-user item or product is what separates us from the rest. Ask us how we do it.

We Use Top Notch Materials

Highest Quality Materials. Highest Quality Products. Guaranteed.

PLA – Polylactic Acid is a common plastic used for 3D printing. Both versatile, bio-degradable and cost-effective, this is the recommended material for printing.

Nylon – Commonly used for its chemical resistance, but being weaker and not as stiff as PLA or ABS, this material is not as widely used for 3D printing.

ABS – Acrylonitrile Butadiene Styrene; stronger and stiffer than PLA, this material is best used for applications which require long lasting structural capabilities.

Metal Filled PLA – A stronger version of PLA infused with metal shavings to create a metallic-effect and stronger material.

Wood Filled PLA – An alternative to traditional PLA for more natural-looking prints. Excellent for printing overhangs without supports up to angles of 67º.

PETG – A great alternative to PLA when water resistance and robustness is required. Being far more ductile than other materials, this is a great material when used in conjunction with moving parts and a degree of flexibility is required. PETG is also food-safe and is great for printing for the hospitality sector.

ASA – The stronger brother of ABS with great heat-resistance properties as well as having great weather resistance.

ABS Pro – A better version of ABS with greater heat and shrinkage resistance.

Ultra Strong PLA – All the benefits of PLA but stronger.

TPU & TPE – Flexible rubber-like material, similar to what you would find on RC car tyres. Great for printing phone cases, non-slip product bottoms and flexible non-stressed parts.

The 3D Printing Process

At this stage we review your design, or if opting to have a design created from scratch, we will consult to find out your requirements and the proposed use. We will discuss the choice of material and deliver a time-frame.

This is the stage when your part gets printed. Depending on the choice of material, complexity and size; this stage can take 5 hours to a few days.

This is the stage where the print is processed, if required, to appear as though it was injection moulded. For a seamless product that is free of layer lines, this is a crucial stage; especially if progressing onto Hydrodipping or Gold Plating.

This is the most anticipated stage, and your eagerly awaited part is now on its way to its final destination.

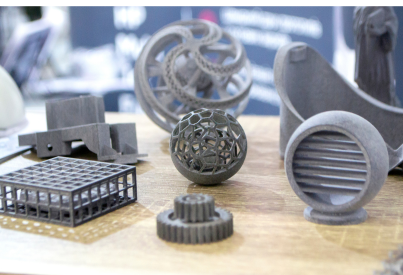

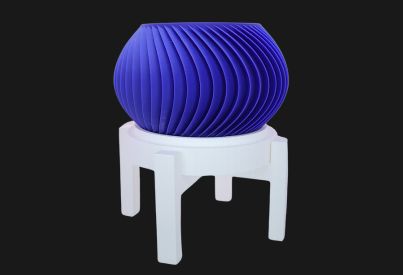

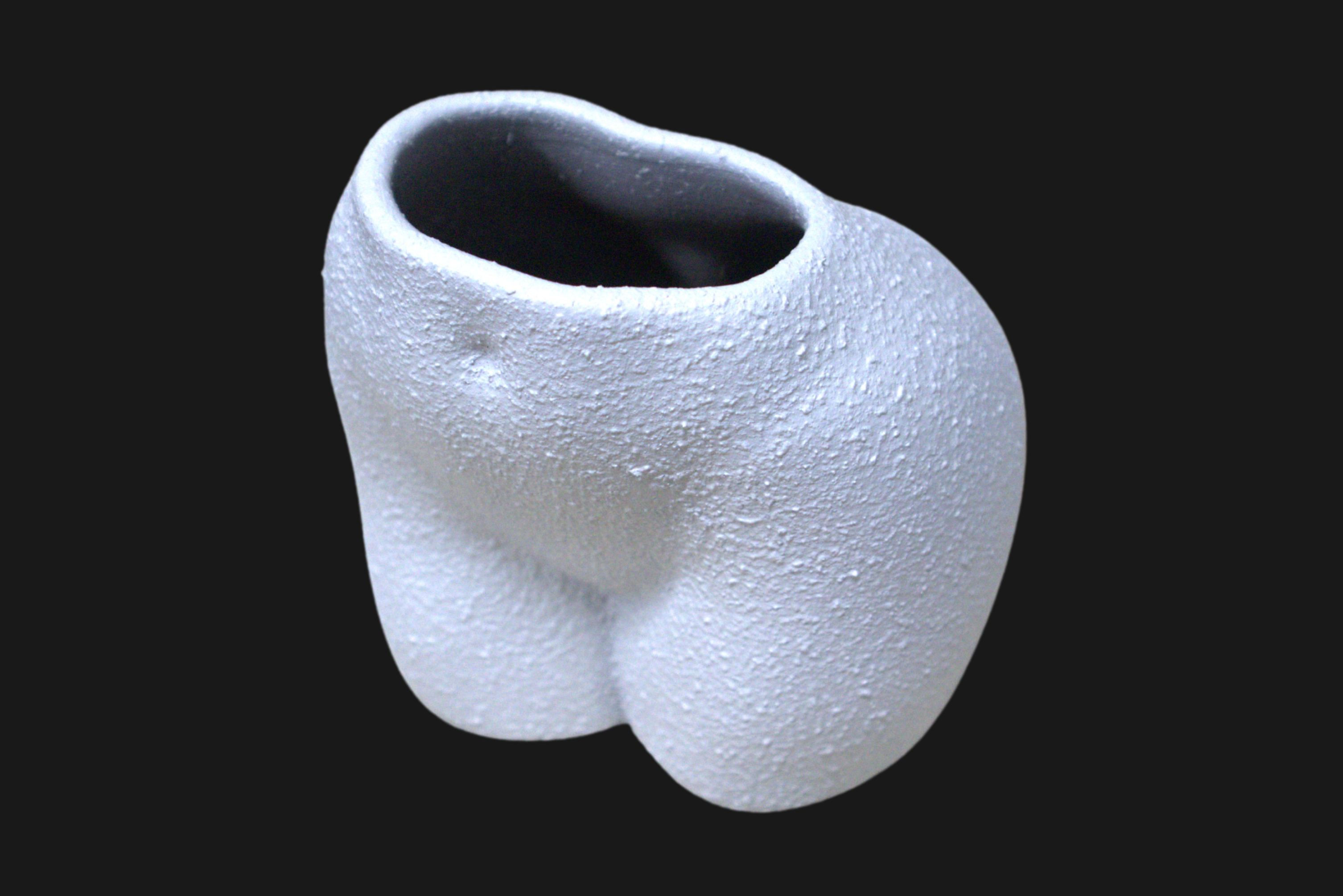

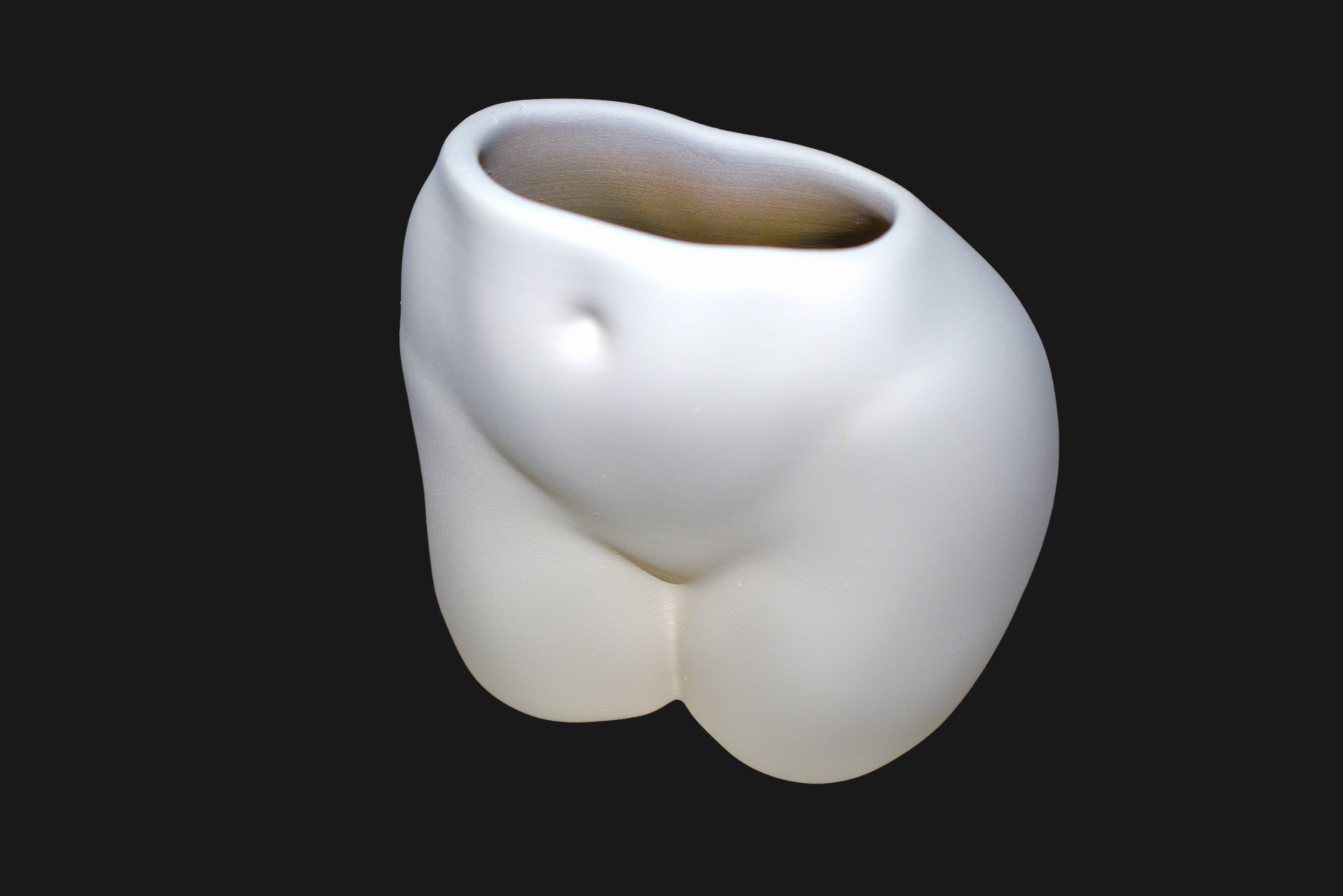

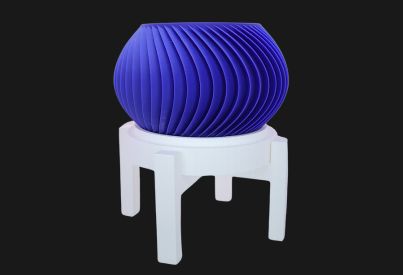

Gallery of 3D printed parts

Below are some snapshots of what 3D printing can achieve, but are not limited to the below. Get in touch to discuss your requirements and see if 3D printing is the right for you

What can we do for you?

- Functional Parts

- Prototyping

- Bespoke Design

- Artwork

- Figurines