Prototype. Prototyping. Done.

Building Products. One Part at a Time.

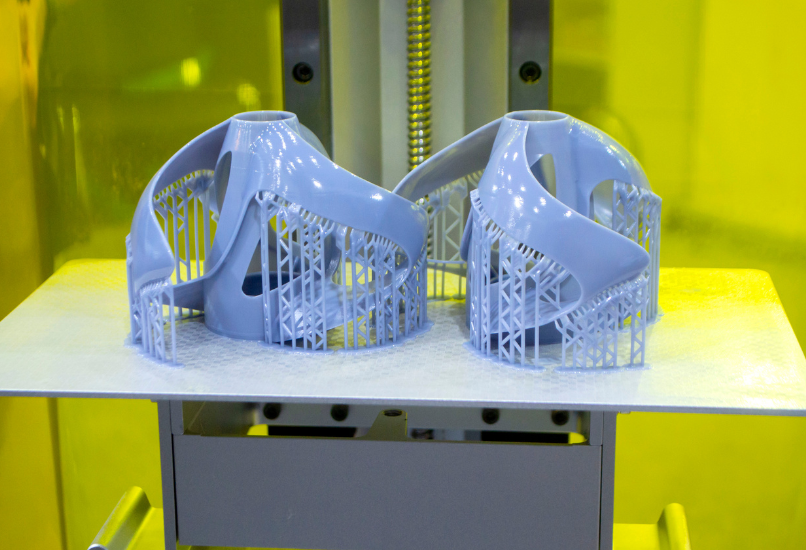

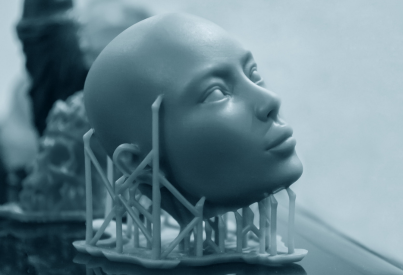

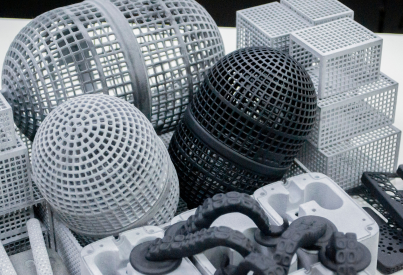

Rapid prototyping for product conception and functional parts. We have a host of materials that can be utilized for different applications. Get in touch to discuss your requirements, and which material would work best for you.

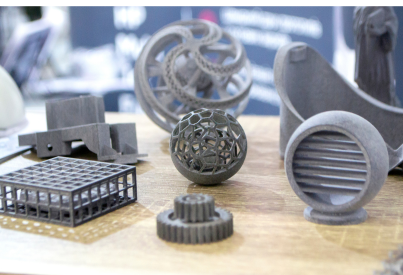

Gears & Cogs

Strong Low-Torque Gears & Cogs

Functional Items

Working Items with a Working Life-Span

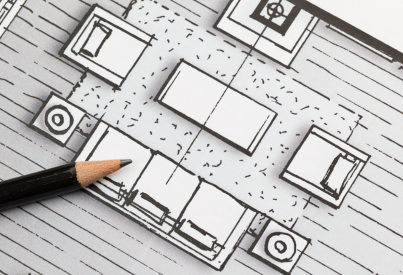

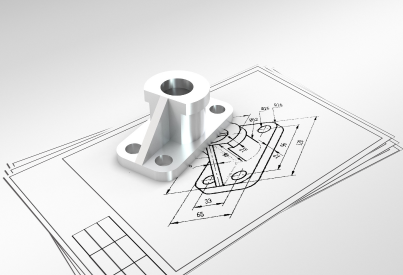

Preliminary Design

Design Conception for Test, Analysis & Review

We Use Top Notch Materials

PLA – Polylactic acid is a common plastic used for 3d printing. Both versatile, bio-degradable and cost-effective, this is the recommended material for printing.

Nylon – Commonly used for its chemical resistance, but being weaker and not as stiff as PLA or ABS, this material is not as widely used for 3D printing.

ABS – Acrylonitrile Butadiene Styrene; stronger and stiffer than PLA, this material is best used for applications which require long lasting structural capabilities.

Metal Filled PLA – A stronger version of PLA infused with metal shavings to create a metallic-effect and stronger material.

Wood Filled PLA – An alternative to traditional PLA for more natural-looking prints. Excellent for printing overhangs without supports up to angles of 67º.

PETG – A great alternative to PLA when water resistance and robustness is required. Being far more ductile than other materials, this is a great material when used in conjunction with moving parts and a degree of flexibility is required. PETG is also food-safe and is great for printing for the hospitality sector.

ASA – The stronger brother of ABS with great heat-resistance properties as well as having great weather resistance.

ABS Pro – A better version of ABS with greater heat and shrinkage resistance.

Ultra Strong PLA – All the benefits of PLA but stronger.

TPU & TPE – Flexible rubber-like material, similar to what you would find on RC car tyres. Great for printing phone cases, non-slip product bottoms and flexible non-stressed parts.

Unsure which material would service your project best? Get in touch with us and we would be happy to help.

Prototyping. Done Right.

A small compilation of items that we have printed.

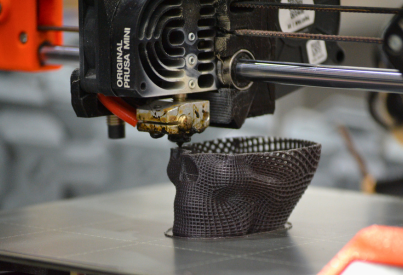

The Prototyping Process

At this stage we review your design, or if opting to have a design created from scratch, we will consult to find out your requirements and the proposed use. We will discuss the choice of material and deliver a time-frame.

At this stage tolerances are reviewed, and shrinkage allowed to ensure that the part is as per the design, and any fitment down the line is snug.

This is the stage where your part is printed, and tolerances are analysed for best fitment. Once this has been reviewed and the part functions as intended, we would then move onto the processing stage.

At this stage the part will be processed to achieve the desired finish, whether that is a Painted, Hydrodipped, Gold Plated, Clear Coat, Sanded or Rough finish would be down to your requirements.

At this stage the part would be tested prior to dispatch to ensure that we have ticked all the boxes prior to final delivery for end-use. A keen attention-to-detail is paramount at this stage to ensure satisfaction and longevity.

This is the most anticipated stage, and your eagerly awaited part is now on its way to its final destination.

Your Prototype, our Expertise!

- Product Housing & Exterior Shell

- Low Torque Gears & Cogs

- Functional Working Parts

- CAD Design & Review

- Home Decor